Choosing the best method for greasing bearings is a “horses for courses” process. Site specific circumstances usually demand a mix of manual lubrication, single-point automatic lubricators and centralised systems.

Whilst automation does cut manual work loads it should not replace the maintenance requirement to regularly inspect equipment. perma lubricators are not 'set and forget' - they do not replace the need for maintenance personnel to visit and inspect.

Time & Resource Efficiency

A growing reason for moving away from manual greasing to automated solutions is the need to implement safer work methods. The increasing rate of adoption of automated systems can deliver greasing time reductions of around 80%*. This translates to 80% less exposure to possible work place accidents associated with manual greasing.

perma recommends that the time liberated from manual greasing tasks, by the introduction of automated systems, be invested into other value adding maintenance and condition monitoring practices.

Simple Statistics Relating to Repetitive Strain Injury

A perma Star Vario L250 lubricator set to 6 months will deliver 0.5cc of grease every 4 hours and 30 minutes over the 6 month period. To deliver the same volume of grease using a typical pistol grip manual grease gun a lube technician would need to complete around 360 pumps. Meanwhile, if a typical lever action gun was used around 180 pumps would be required.

Remote Mounting for Safer Greasing

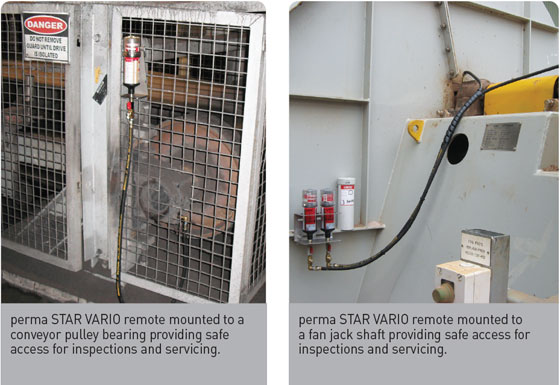

Another safety related benefit associated with the correct us of automatic lubricators is the opportunity to remote mount products such as the perma Star Vario and perma Pro MP6 in order to locate the lubricator at a safe and easy to access point.

The examples below demonstrate some of the simple, safety related benefits:

Figure 1 - The images below demonstrate the value of remote lubricator installations whcih allow safe access to single point lubricators while equipment is operating.

www.perma-tec.com

|